Working hours:Mon - Fri 8:00 - 3:30Call Us: (+1) 905.579.9721

Manufacturing

Globally – We are proud to be PR!

PR Engineering is one of the few companies worldwide specializing in the complete remanufacturing, repair, service and support of key parts and components to most makes of crushers. In addition to servicing crushers, PR Engineering also designs and manufactures its own line of crushers.

Precision and Quality – Customer Satisfaction

It is the mission of PR Engineering to provide its customers with high quality products and services. A Quality System designed by PR adheres to strict standards and practices consistent with the company’s reputation. Committed to quality and customer satisfaction is what makes PR stand out!

Services

We offer a variety of services, these are all displayed below

Crusher Manufacturing

Babbitting

CNC Machining

Fabrication & Welding

Replacement Wear Part Supplier

OUR VALUED CUSTOMERS

We service the following industries globally from our facility in Oshawa, Ontario.

- Mining

- Aggregates

- Steel

- Pulp & Paper

- Power Generation

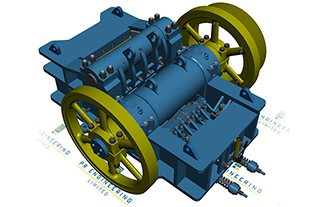

Jaw Crushers

High Performing Jaw Crushers

We’ve also demonstrated COMMITMENT to this industry by designing and manufacturing our own line of Jaw type crusher, Birdsboro Buchanan, ranging in size from 24×36 up to 66×84 Deep frame, capable of 1050 tons per hour throughput.

We have the capability to repair other makes of jaw type and cone crushers as well as vibratory screening equipment.

Fabrication & Welding

- 100 combined years of welder experience ready to fabricate for you

- CWB Division 2 certified company since 1980

- Developers of many Pre-Qualified Procedures

- Fabrication using FCAW, SMAW, and SMAW

- Qualified and equipped to handle custom fabrication and all type of repairs

- Non-destructive testing capability

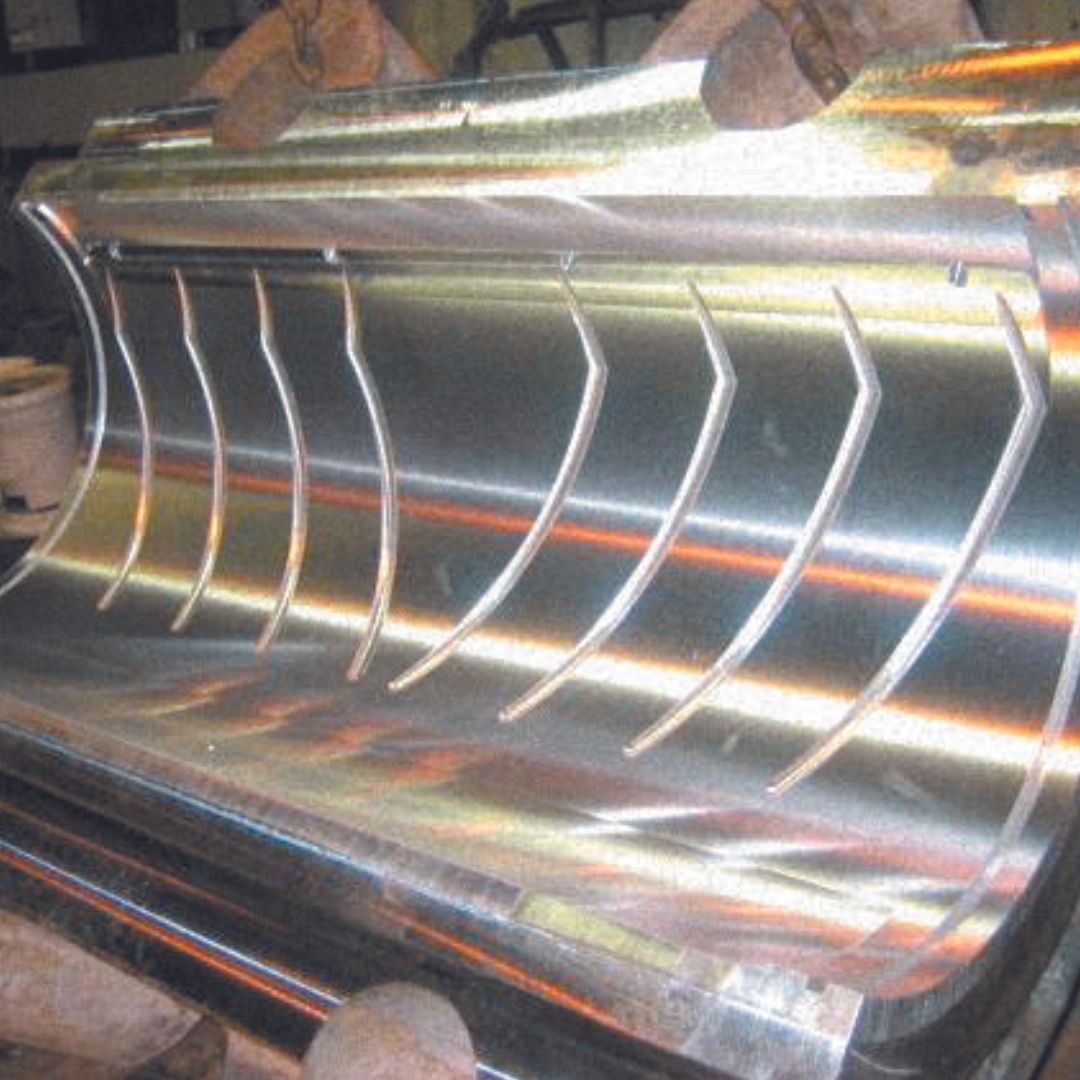

Machine Center

- Over 182 years of machining experience ready to serve your crushing needs

- More than 12 industry-leading machines to provide the repair service you require

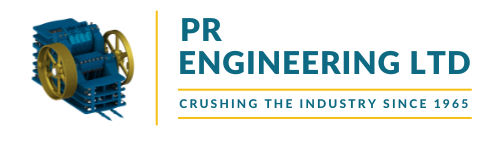

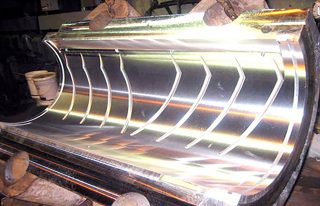

Babbitting

- Experience and capability to Babbitt new or re-babbitt bearings ranging in size from 4″ x 108″ using any type of babbitt

- We pour more than 200,000 lbs. of babbitt each year

PR Engineering is a proud dealer of the HYDRAULIC TOGGLE ASSEMBLY

Improve Safety and Increase Throughput with a Hydraulic Toggle Assembly

Reduce Risk of Injury

- The hydraulic adjust assembly is designed to fit into the area that is occupied by the Solid toggle. The assembly can be installed or removed with minimal or normally without any alteration to the existing jaw crusher

- The in risk of injury associated with adjusting the jaw opening sizes is greatly reduced with the installation of the hydraulic adjust cylinder assembly. Simply use hydraulics to increase or decrease the crusher setting size (CSS). Risk of injury is also reduced from the shimming process

Increased Production Rates

- Through put is improved as the downtime required to manually shim and adjust the jaw crusher setting for various aggregate sizes (CSS) is eliminated by the efficiency of using hydraulics rather than the manual task of adding or reducing shims in the jaw crusher

- Little effort is required for operators to adjust the opening as frequently as jaw wear warrants

- Design to relieve the high-pressure fluid back to the reservoir if uncrushable material falls into the jaw.

- Infinite jaw settings due to hydraulic system

- High-Quality alloy steel construction to withstand the rigors of time

- Long-lasting value and high return on investment